WE ARE MANY.

WE ARE RAILFANS.

Railfan-Guest

September 2nd, 2021

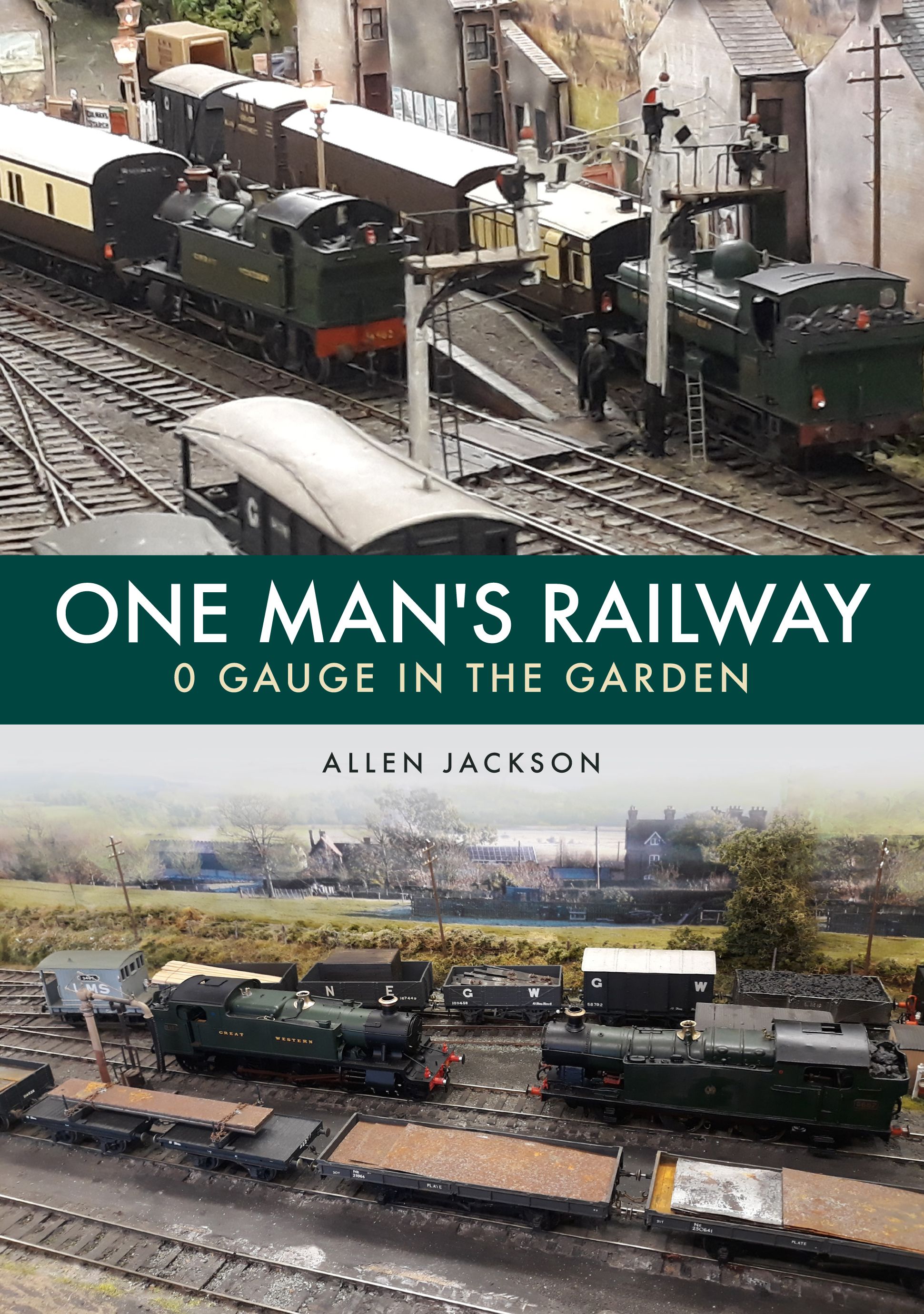

As a child, Allen Jackson remembers vividly his father taking him to visit the pathway by York's north engine sheds, now home to the National Railway Museum. From there, with steam engines running up and down the East Coast Main Line and mineral waggons moving coal around the coaling plant, there was much to inspire an enthusiasm for railways and modelling too. In this article, Allen guides us through his O Gauge garden railway, which features in this latest book: O Gauge in the Garden.

Words and images by Allen Jackson.

A model railway often sets out as an entity within a room and it usually describes an orbit in its early form. The notion of a ‘train set’ where a locomotive, some rolling stock and often an oval of track, is one familiar to many. The railway I built takes the model railway to operate between separate buildings and hence have a start point and a destination much as the real ones do. There is something very satisfying about a train disappearing from view as it sets out on a journey and something even more satisfying about it reaching its destination safely, particularly if it’s your own train. This is the romance of railways, the tearful farewells, the expectations of a journey.

Although the term ‘Garden’ is used, by which I also mean ‘Yard’ in a US context, the layout I built is strictly speaking not a garden railway in terms of G scale or SM32 than runs among the plants and herbs. I have done that in Britain and it usually precludes all year round running unless you are in Southern California or Florida. No, this railway is O Gauge that runs between three sheds or light buildings with the railway protected from the elements in between and the operators similarly protected in their cosy buildings. We run all year round and as the sheds are at least 2 metres (six foot six and a bit inches) apart we ran in lockdown as the rules allowed.

The location chosen for the model, Brymbo, is a place in North Wales, the nearest city being Chester over the border in England. This enabled the use of three of the four main railway companies that existed in the 1930s, namely, The Great Western, London and North Eastern and the London Midland and Scottish. This didn’t happen often in Britain but sometimes, like Union Station in Washington D.C., companies came and worked together, almost. North Wales had mineral riches of coal, limestone and lead. These riches clustered the companies around the area looking to expand their operations. A steelworks was established at Brymbo which survived until 1990. This meant lots of traffic and work for the railways and a hint of that is attempted on the model.

The model locations are fictitious as the real thing could not be accommodated in a relatively small area but the flavour of the area has been kept with typical buildings of the real location. The railway has working signals which are LED lit, interlocked with the point motors. This circuitry has been home made using relays and diodes. There are two signal boxes/interlocking towers, one at each station. There are no semaphore signals at the fiddle yard, which represents the rest of the railway network, only indicator LEDs.

Trains are moved around the layout using a system developed in the 1870s and still in use in parts of Britain and on preserved lines. Operators communicate with each other using block apparatus from the 12 inches to the foot railway and the equipment is mostly in period. We have telephones too which are wireless landline phones used in intercom mode. You allocate each phone a number and that is the number printed on the other phones to dial that phone.

The railway is run to a sequence of 50 moves and this takes the three operators about 2½ hours to complete. The only freight wagon shunting is at Crowndale Halt which only sees 18 of the sequence moves. This is to ensure something is running almost all the time and everyone is mostly fully occupied. A former signalman on the real thing declared ‘it was like putting in a shift only busier.’ CCTV cameras assist the operators to hand over or take over trains from an operator as the hand over points are all outside the shed buildings. There are also cameras at the fiddle yard to keep an eye on what is in Watery Yard and on summer days they can look outside and be outside but in winter the lure of the gas heater is too much. Some of the CCTV cameras have lighting but the cameras are all of the infra-red LED type.

The locomotive stock is a mixture of kit-built, bought in and proprietary. It has to be this way unless you don’t want a life outside trains. I built seven of the locos from kits and an advanced one like the Martin Finney Collett 2251 Class took about six months, off and on. The goods rolling stock is nearly all kit built but the coaches are all bought in. There is about as much work in a corridor coach as a small locomotive.

The signals are scratch built using etched components as is the point rodding which is the lever worked way of operating points/turnouts from a signal box/tower. In reality all points/turnouts are electrically operated, except for the fiddle yard inside shed, and they are interlocked with the signals where needed. Signals are not interlocked with the block instruments as that process was only begun on the main lines in 1935 and not on branch lines by then. This was as a result of the accident at Welwyn Garden City north of London Kings Cross station.

The buildings are scratch built except the Brymbo East Junction tower/signal box which is a Churchward Models etched kit. Both signal boxes have interior lights and detail including single line apparatus and BEJ has two. The scenery is nothing patent with teased dyed carpet felt, static grass, sawdust, plaster and miniature heather as some trees. Some of the areas under CCTV surveillance are scenicked but this is a work in progress. The back scenes are photographs by Gaugemaster.

Tea, coffee and water is provided at the beginning of a run on Tuesdays and similarly at the end with a light lunch and a lie down in a darkened room as an option or more usually a trains related video. They keep coming back.

Figure 1. A simplified diagram of the railways around Wrexham and Brymbo, as modified for the Brymbo East Junction model. The Great Western (GWR) main line through Wrexham to Birkenhead and Liverpool ran through here but the London and North Eastern (LNER) and London Midland and Scottish (LMSR) only got here by branch lines.

Figure 1. A simplified diagram of the railways around Wrexham and Brymbo, as modified for the Brymbo East Junction model. The Great Western (GWR) main line through Wrexham to Birkenhead and Liverpool ran through here but the London and North Eastern (LNER) and London Midland and Scottish (LMSR) only got here by branch lines.

Figure 2. This is an overview of the model railway layout in block form showing the areas of control, one operator for each differently coloured area and each operator has their own CCTV cameras to cover that area of control but the views from the cameras are duplicated to some extent such that the Crowndale Halt operator, for example, sitting in the purple area in that shed can see the changeover/handover point view from camera 6 between the blue and green areas. This gives the Crowndale Halt operator advance warning that a train bound for that shed is on its way, also a pair of binoculars is provided in the Crowndale Halt shed.

Figure 2. This is an overview of the model railway layout in block form showing the areas of control, one operator for each differently coloured area and each operator has their own CCTV cameras to cover that area of control but the views from the cameras are duplicated to some extent such that the Crowndale Halt operator, for example, sitting in the purple area in that shed can see the changeover/handover point view from camera 6 between the blue and green areas. This gives the Crowndale Halt operator advance warning that a train bound for that shed is on its way, also a pair of binoculars is provided in the Crowndale Halt shed.

Figure 3. Crowndale Halt track layout. In a 7 by 8 foot shed in O Gauge the run round point has to be outside the shed to ensure three coaches can be run round. The shed is on the extreme left of the garden overview at Figure 2. A conventional small terminus with limited goods yard facilities. The small signal indicates the freight departure road as using the loop line would inhibit a passenger train running round. Both smaller signals are interlocked with the throat point, as is the platform starter signal. There should be a bracket signal on the way into the station and that will get built at some point. Crowndale Halt is the only place on the layout where goods train shunting takes place. The coal trains, empties and steel products trains at Brymbo East Junction are merely turned around. There are two LMS pickup goods and one GWR pickup in the sequence. Crowndale Halt has a dedicated yard shunter and even a spare loco is provided. There are two complete trains here at the beginning of a sequence, the Sunday school excursion and the LMS pickup goods.

Figure 3. Crowndale Halt track layout. In a 7 by 8 foot shed in O Gauge the run round point has to be outside the shed to ensure three coaches can be run round. The shed is on the extreme left of the garden overview at Figure 2. A conventional small terminus with limited goods yard facilities. The small signal indicates the freight departure road as using the loop line would inhibit a passenger train running round. Both smaller signals are interlocked with the throat point, as is the platform starter signal. There should be a bracket signal on the way into the station and that will get built at some point. Crowndale Halt is the only place on the layout where goods train shunting takes place. The coal trains, empties and steel products trains at Brymbo East Junction are merely turned around. There are two LMS pickup goods and one GWR pickup in the sequence. Crowndale Halt has a dedicated yard shunter and even a spare loco is provided. There are two complete trains here at the beginning of a sequence, the Sunday school excursion and the LMS pickup goods.

Figure 4. Brymbo East Junction shed track layout. The signalling must seem a bit busy but it is only what is required for a single track branch line and although a couple of ground disk signals have been modelled whereas there would have been several in reality to cover movements in either direction. The two sidings at the bottom of the board inside the shed are for waiting coal trains. The bay platform is for the Plas Power push-pull autotrain and a van train for the loading dock. The workman’s carriage siding just accommodates three four wheeled coaches, a van and a tank locomotive. All of the shed’s thirteen controllable signals are controlled by the Brymbo East Junction operator and each line out, that is GW/LMS to Crowndale Halt, GW to Wrexham (Fiddle Yard) and LNER to Plas Power (Fiddle Yard) has its own set of block instruments. There are four complete trains here at the beginning of a sequence.

Figure 4. Brymbo East Junction shed track layout. The signalling must seem a bit busy but it is only what is required for a single track branch line and although a couple of ground disk signals have been modelled whereas there would have been several in reality to cover movements in either direction. The two sidings at the bottom of the board inside the shed are for waiting coal trains. The bay platform is for the Plas Power push-pull autotrain and a van train for the loading dock. The workman’s carriage siding just accommodates three four wheeled coaches, a van and a tank locomotive. All of the shed’s thirteen controllable signals are controlled by the Brymbo East Junction operator and each line out, that is GW/LMS to Crowndale Halt, GW to Wrexham (Fiddle Yard) and LNER to Plas Power (Fiddle Yard) has its own set of block instruments. There are four complete trains here at the beginning of a sequence.

Figure 5. This is the final destination and originating point for all trains, the fiddle yard. The fiddle yard operator has two controllers and whilst this may seem like a burden it actually makes life easier giving time to organise the yard whilst a train is on its way to or from the yard. Each of the numbered sidings can hold two complete standard trains and the loop lines inside the shed similarly but of lesser length. The sector plate siding and headshunt can accommodate light engines or an autotrain and the GWR pickup siding is limited to eight wagons plus tank locomotive. There are no working signals here but there are two sets of block instruments. There are ten complete trains here at the beginning of the sequence and they all fit inside the shed when we are not running. Halfway between the fiddle yard and the junction is a mobile phone earpiece that acts as a microphone whose signal is amplified and played in the fiddle yard. This means that the fiddle yard operator knows roughly where the train is ascending or descending the 1 in 60 gradient. Track joints have been opened up to accentuate the clickety-clack feature.

Figure 5. This is the final destination and originating point for all trains, the fiddle yard. The fiddle yard operator has two controllers and whilst this may seem like a burden it actually makes life easier giving time to organise the yard whilst a train is on its way to or from the yard. Each of the numbered sidings can hold two complete standard trains and the loop lines inside the shed similarly but of lesser length. The sector plate siding and headshunt can accommodate light engines or an autotrain and the GWR pickup siding is limited to eight wagons plus tank locomotive. There are no working signals here but there are two sets of block instruments. There are ten complete trains here at the beginning of the sequence and they all fit inside the shed when we are not running. Halfway between the fiddle yard and the junction is a mobile phone earpiece that acts as a microphone whose signal is amplified and played in the fiddle yard. This means that the fiddle yard operator knows roughly where the train is ascending or descending the 1 in 60 gradient. Track joints have been opened up to accentuate the clickety-clack feature.

Figure 6. 6412- GWR 64XX pannier is a Castle Kits cast kit and usually works the 163 Autocoach to Plas Power Halt (GC-LNER). This engine was built in 2006. Here seen arriving at Brymbo East Junction. Sep 2018. The 4588 Prairie locomotive is by Sang Cheng Crafts and together with the three clerestory coaches in the platform form part of an excursion to Chester that will join up with the LMS for Llanberis and day out up Mount Snowdon. Two empty coal trains await a path up the LNER branch back to the coal mine at Plas Power. September 2018.

Figure 6. 6412- GWR 64XX pannier is a Castle Kits cast kit and usually works the 163 Autocoach to Plas Power Halt (GC-LNER). This engine was built in 2006. Here seen arriving at Brymbo East Junction. Sep 2018. The 4588 Prairie locomotive is by Sang Cheng Crafts and together with the three clerestory coaches in the platform form part of an excursion to Chester that will join up with the LMS for Llanberis and day out up Mount Snowdon. Two empty coal trains await a path up the LNER branch back to the coal mine at Plas Power. September 2018.

Figure 7. Brymbo East Junction station throat looking towards the junction. The purpose of the trap point in the middle of the picture is to protect the passenger carrying line and it works in concert with the point that connects passenger and goods lines. On the prototype this is achieved with point rodding which has been modelled but in model form there is a separate point motor. Catch points are used where runaway vehicles on gradients usually against the normal direction of travel are derailed to prevent a collision with following trains. April 2020.

Figure 7. Brymbo East Junction station throat looking towards the junction. The purpose of the trap point in the middle of the picture is to protect the passenger carrying line and it works in concert with the point that connects passenger and goods lines. On the prototype this is achieved with point rodding which has been modelled but in model form there is a separate point motor. Catch points are used where runaway vehicles on gradients usually against the normal direction of travel are derailed to prevent a collision with following trains. April 2020.

Figure 8. Crowndale Halt station throat and the GWR Mogul on the left is waiting to depart with the Sunday School excursion whilst we can just see the nose of the LMS pickup goods engine waiting its turn to follow later. The two shorter signals are not in the usual place at the left hand side of the track but railways would move them when sighting or other issues dictated. The gantry across the tracks is the support for the signal box/tower which is elevated above the tracks. A few railways in Britain and Ireland favoured this approach. The portcullis protecting the innards of the shed is closed so we are at the beginning of a sequence. October 2020.

Figure 8. Crowndale Halt station throat and the GWR Mogul on the left is waiting to depart with the Sunday School excursion whilst we can just see the nose of the LMS pickup goods engine waiting its turn to follow later. The two shorter signals are not in the usual place at the left hand side of the track but railways would move them when sighting or other issues dictated. The gantry across the tracks is the support for the signal box/tower which is elevated above the tracks. A few railways in Britain and Ireland favoured this approach. The portcullis protecting the innards of the shed is closed so we are at the beginning of a sequence. October 2020.

Figure 9. Watery Yard outside the fiddle yard contains a fair selection of trains and they are placed there mindful of which one is needed first, second, third and so on. Some operators just ‘wing it’ others need to have it written down what fits where and when from a scene that is constantly changing. This is in addition to the five loops and three sidings within the actual fiddle yard shed. The polycarbonate lids are shut in bad weather. April 2021.

Figure 9. Watery Yard outside the fiddle yard contains a fair selection of trains and they are placed there mindful of which one is needed first, second, third and so on. Some operators just ‘wing it’ others need to have it written down what fits where and when from a scene that is constantly changing. This is in addition to the five loops and three sidings within the actual fiddle yard shed. The polycarbonate lids are shut in bad weather. April 2021.

Figure 10. From time to time diesel motive power is used and this brings the layout from 1936 to about 1968, whilst all the rolling stock remains the same there are eight diesels to run the reduced service compared with 20 steam engines plus spares. British Railways Class 08 diesel shunter/switcher, by DAPOL, competently tackles 26 wagons up the 1 in 60 gradient into the fiddle yard. December 2016.

Figure 10. From time to time diesel motive power is used and this brings the layout from 1936 to about 1968, whilst all the rolling stock remains the same there are eight diesels to run the reduced service compared with 20 steam engines plus spares. British Railways Class 08 diesel shunter/switcher, by DAPOL, competently tackles 26 wagons up the 1 in 60 gradient into the fiddle yard. December 2016.

O Gauge in the Garden is available to buy through Amberley Books.

https://www.amberley-books.com/one-man-s-railway-0-gauge-in-the-garden.html

O Gauge in the Garden is available to buy through Amberley Books.

https://www.amberley-books.com/one-man-s-railway-0-gauge-in-the-garden.html